Technical Proposal for Aluminum & Plastic Recycling Line

Application: It is mainly used for aluminum-plastic separation of various aluminum-plastic pipes, aluminum-plastic bottle caps, aluminum-plastic panels, aluminum-plastic flexible packaging and medical boards and other raw materials containing aluminum. It can also be used for various copper wires and cables and other plastics Separation and recycling of products.

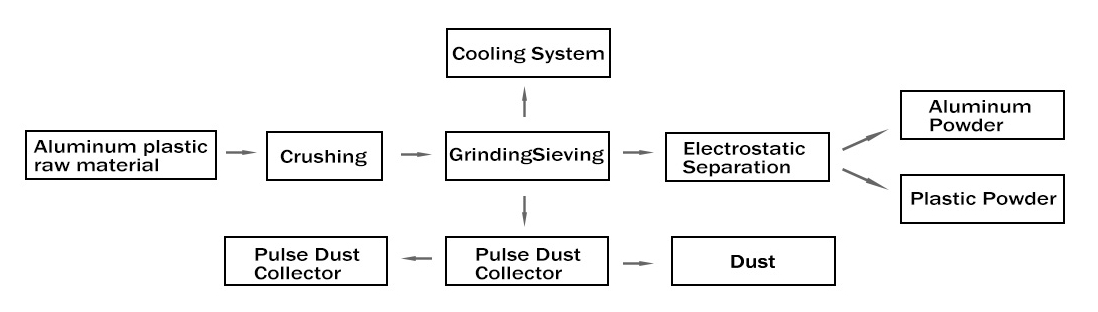

Description: Using the technical process of crushing, grinding, separation and dust removal, the complete simultaneous separation and recycling of aluminum metal and plastic powder is realized. The recycled aluminum powder can be directly sold to aluminum recycling plants, and the PVC powder can also be sold in the market as a reprocessed material.

Workflow: The aluminum-plastic material is first broken into small pieces of 10mm with a knife crusher, and then ground into aluminum-plastic fine powder by a water-cooled turbo grinder. After separation by rotary sieve, the large powder returns to the mill, and the fine powder enters the electrostatic separator, and finally the aluminum and plastic are separated.

Advantages:

1. All processes are separated physically, without heating, burning water and chemicals, so it is very environmentally friendly and has no pollution.

2.Low cost, high efficiency, separation rate of 99.8%

3.The automatic production line saves labor.

4.Easy to install, there are various assembly methods, suitable for different places.

5.Use the water cooling and wind cooling turbo type grinding machine, make the grinding efficiency higher, and process more kinds of raw materials.