Aluminum Plastic recycling plant is suitable for waste soft packaging bags, capsule board, toothpaste skin, aluminum-plastic board, medicine board, aluminum foil, aluminum-plastic film and other aluminum-plastic composite materials. The aluminum plastic recycling and separating plant through physical crushing aluminum-plastic composite materials and plastic powder separation. At the same time, the AL-plastic recycling plant is also equipped with pulse dust removal equipment, effectively solve the dust generated in the production process. The subsequent use of high-voltage electrostatic separator makes the sorting more precise and efficient, effectively controls the loss of non-ferrous metals, and the metal sorting rate is as high as 98%. So that the loss of aluminum and plastic are very low, aluminum reuse rate is close to 99%.

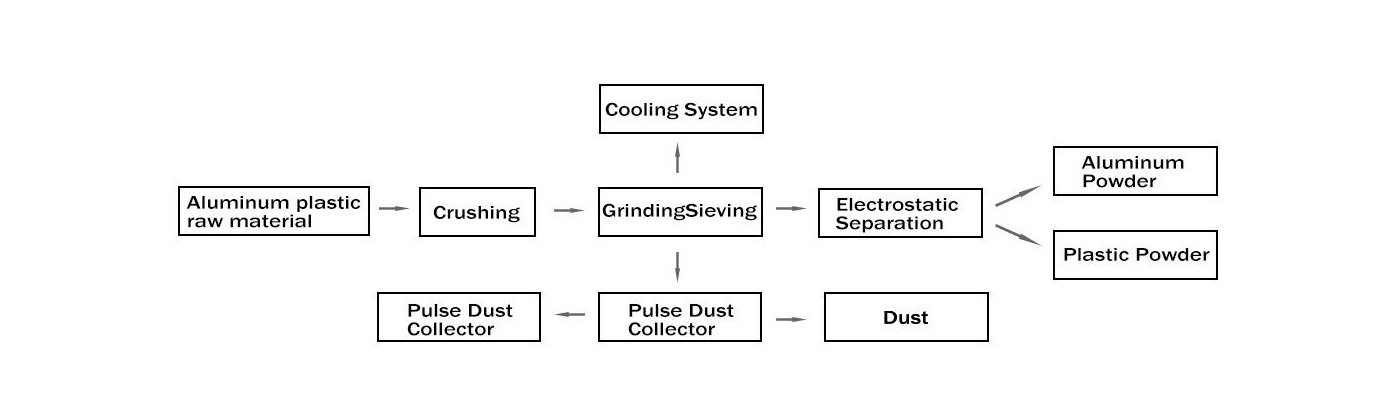

First through the knife crusher coarsely crushed into the following 10 mm sheet material, it then enters a high-speed cold water turbine mill to pulverize the sheet into a mixture of aluminum and plastic, the spin vibration sieve screening materials conform to the requirements by using the theory of electrostatic separator separating the aluminum and plastic, unqualified material returned to mill continue to crush and then through the electrostatic separation of aluminum and plastic powder separation process. To prevent dust pollution in the production process, add pulse dust removal device after grinding, effectively solve the problem of dust pollution.

High automation program, simple operation, stable performance;

Low power consumption, low noise, small footprint, no dust pollution;

Electrical separation efficiency of 99%, the finished products can be directly sold;

Wide range of sorting materials, sorting speed is fast;

No waste gas emissions, real green environmental protection sorting, no secondary pollution generation;

The aluminum-plastic sorting and recycling equipment adopts water-cooled and air-cooled turbine mill, which makes the material separation cleaner and more suitable for a wider variety of materials.

|

Model |

Capacity(kg/h) |

Power(kw) |

Dimension L/W/H(mm) |

|

RNB-LS 300 |

200-300 |

70 |

7500*6000*4200 |

|

RNB-LS 500 |

300-500 |

115 |

9500*7500*4200 |

|

RNB-LS 1000 |

800-1000 |

215 |

11500*800*4200 |

Note: 1. The above machine is our standard configuration, but for different raw materials, it is different machine configuration, so please contact us about your raw materials; 2. The machine voltage can be customized.

Recommended by the company